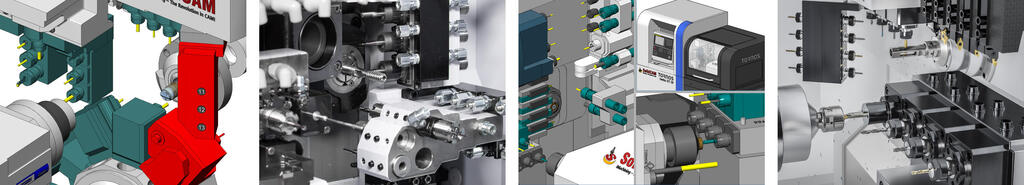

The revolutionary software that optimizes the manufacturing processes of Swiss-Type CNC machines

Swiss-Type CNC machines are used to manufacture extremely small and precise parts, with tight tolerances, rapidly and accurately in many industries, including spinal and dental implants to medical instruments to miniature aerospace components. With the help of SolidCAM’s advanced CAM software, CNC machine shops can significantly optimize their Swiss CNC processes. The machining, which includes combined milling and turning operations, synchronized in several channels, can be optimized, with great savings in machining time, resources, and personnel. Many Israeli companies have already discovered the advantages that come with using SolidCAM for Swiss-Type CNC machines, including Rav Bariah, Tag Medical Devices, Noga Engineering, Alpha Bio, Hamlet Israel-Canada, and Cortex.

In recent years, more companies in the CNC manufacturing field, have started using Swiss-Type CNC technology, kickstarting a revolution in their manufacturing processes. These advanced CNC machines can produce miniscule complex parts, with diameters of only 10 to 30 mm, in several channels at the same time, at record speed and with a very high level of precision.

Parts manufactured by Swiss-Type CNC machines can be found in a variety of industries and products, ranging from high-tech, electronics, medical devices, dental and orthopedic implants, optics, automobiles, aviation, defense industries and more. The most popular Swiss-Type machines today are STAR, CITIZEN, TSUGAMI, HANWA, INDEX, TORNOS, NEXTURN and more.

Until recently, to operate Swiss-Type machines, workshops were required to directly program the controller of the CNC machine, a skill that only a few specialists in the market can master. In fact, every owner of a machining factory or workshop, that uses these kinds of machines, knows the degree of difficulty in finding sufficiently experienced professional personnel, who know how to operate and program on the controller these machines, in a manner that reduces (but does not prevent!) the risk of malfunctions and damage to the machine, during the complex programming phase.

And what happens when that expert retires, leaves the workplace or is absent due to vacation or illness? The machine shop owner is at risk of being left with a CNC machine, that none of his employees can program or operate. Also, the same specialist is required to produce an initial master part for testing, to ensure that the rest of the production series will run smoothly and without faults. If a mistake is made in programming the controller, the machine shop owner can find himself with risk of damage to the part, cutting tools or to the CNC machine itself - practically, this can mean significant economic damage to the workshop profits. Since these machines are designed to produce parts in several machine channels at the same time, synchronization between the operations in the different channels is required, and there can be significant risk of a malfunction and damage to the machine.

Over the years, many CAM programs have emerged that enable programming of the Swiss-Type CNC machines on an external computer, but most of them did not provide a satisfactory solution. They tend to have a user interface that is cumbersome to learn and operate, they provide inadequate support of the CNC machine functionality and lack sufficient technical support from the software provider.

All of this changed in 2019, when SolidCAM’s breakthrough Swiss software module entered the market. SolidCAM develops advanced CAM solutions and complementary software products for all types and brands of CNC machines and can support the entire manufacturing chain. SolidCAM currently has 24,000 customers around the world, and there are many global companies which have products that are manufactured using the SolidCAM solution. From car manufacturers like Toyota, Honda, Hyundai, Volkswagen, and Skoda, to technology companies like Intel, HP, Facebook, Amazon, Panasonic, Nikon and Canon, to aerospace companies like Airbus and SpaceX, to security industries like Elbit, Rafael and Israel Aerospace Industries, to consumer goods giants such as Procter & Gamble, Bosch and Michelin tires - almost every major company in the world today uses SolidCAM software in their CNC manufacturing processes.

SolidCAM, which was established 38 years ago, is one of the world's leading companies in the field of CAM software for CNC machining. Computerized Numerical Control - or CNC, for short - refers to the precise manufacturing technique of industrial materials, such as metals, plastics, and wood. The manufacturing accuracy of these materials is achieved using two types of software: Computer Aided Design (CAD) and Computer Aided Manufacturing (CAM) softwares. The CAM software is used to define the machining operations needed to manufacture the product model on the CNC machine.

SolidCAM has a lot of experience with optimizing the manufacturing process on Swiss-Type machines.

“With a record of almost 40 years in the field of CAM for CNC machining, SolidCAM really understands the needs of manufacturers and workshops. We studied the Swiss technology in its entirety and analyzed the weaknesses of existing softwares in the market. The result is that our developed product is the smartest, most efficient, most reliable, and most productive CAM software for the Swiss-Type market,"

says Dr. Emil Somekh, founder, and CEO of SolidCAM.

Shortening and optimizing the CNC machining process - a significant advantage in a competitive market

In recent years, the increased competition, and the fast pace of new technological innovations in various markets, also raised the demands on the workshops that produce parts using the Swiss-Type method. If in the past, a workshop would receive a single order from the customer to produce a large series of a part, for a period of months, today workshops are required to manufacture a variety of different parts, taking into account also updates to each of those parts, during its manufacturing. Since Swiss-Type machines work simultaneously on several channels, accurate and safe synchronization is required to achieve optimal results.

This is where SolidCAM comes into the spotlight. The high level of synchronization of the Swiss-Type machines provided by SolidCAM, enables quick, reliable, and foolproof optimization in parts machining. The SolidCAM software provides all the required functionality, both in the machining of parts with a size of a few microns, which are relatively high in cost, and in the manufacturing of multiple series of parts, that require frequent CAM programming. The flexibility, clear interface, and ease of use of the software provide the workshop with the ability to achieve a high production rate, while adapting to the changing demands of the market. The software dramatically shortens the work time and gives a competitive advantage to SolidCAM customers.

2 View gallery

Dr. Emil Somekh, SolidCAM Founder and CEO, Zvika Friedman, VP Sales Israel & Japan, Michael Vinetsky, Senior VP Product Management

(SolidCAM)

Another key advantage of using SolidCAM software on Swiss-Type machines, is the advanced machine simulation capability offered. Even in the pre-manufacturing stages, it’s possible to run an accurate simulation, which can locate potential issues that could damage the manufacturing process or the CNC machine, ultimately leading to economic damage for the factory. Each CAM program can be saved, so that any operator, at any point in time, is able to run it on the CNC machine. It is worth noting that SolidCAM is the only Swiss-Type CAM software today, which is fully integrated in the SOLIDWORKS software, the #1 3D CAD software in the world.

In the development of the innovative Swiss-Type module, Michael Vinetsky, Senior VP of Product Management at SolidCAM, researched the subject in depth, and formulated work plans for the team of software developers. His extensive experience with CNC machines in general, and with combined Mill Turn and Swiss-Type CNC machines in particular, contributed greatly to the final specifications of the product.

A springboard for CNC machine shops interested in entering the Swiss-Type field

Today you’ll find Swiss-Type machines in about 15% of the workshops and factories in the machining market. There is an increasing trend in the portion of workshops seeking to enter the field of Swiss-Type, with the intention of expanding production options, supplying complex parts to industries rich in technology and funds, and increasing their incomes. Therefore, it is necessary to introduce the Swiss-Type CNC machines, that work 24/7, into the production line, performing combined milling and turning operations, working in parallel in several channels. Is that possible? According to Dr Somekh, with the help of CAM software, this goal can become a reality.

"More and more workshops are purchasing these Swiss-type CNC machines, and SolidCAM provides a perfect solution in all aspects: functionality, ease of use, solid simulation and full machine simulation, a POST-PROCESSOR adapted to each controller, as well as one that is capable of synchronizing the special CHANNELS and PATTERNS for each machine."

An international success story among the leading companies in the industry

As soon as it was launched, the Swiss-Type module was incorporated among many of SolidCAM’ s current customers. Following its success, it soon reached new customers who use Swiss-Type CNC machines. The project quickly progressed thanks, among other things, to Zvika Friedman, VP of Sales for Israel and Japan and the director of Israel operations at SolidCAM, who checked the feasibility of the investment with the manufacturing plants and gave a strong backing to the promotion of the project. Friedman understood that the project would place SolidCAM amongst the top companies globally, not only in general CAM, but specifically in the Swiss-Type field. The SolidCAM’s Swiss-Type solution then broke out into the world, with SolidCAM resellers in 70 countries, working aggressively to demonstrate the wonders of the new product to thousands of existing SolidCAM customers and potential new customers. These customers include quite a few of the largest and leading companies in the world, and they have adopted the software with open arms.

The Israeli companies that use the SolidCAM Swiss-type solution include Rav Bariah, which produces small parts for locks; Medical company TAG, which manufactures implants and equipment for orthopedic surgeries, dental implant producers Alpha Bio, AB Dental, Cortex, Bioline, Micromill, Protech Solutions, Cusco Hurident and GOWIZ, a technological incubator that develops dental and medical products. The long list of clients continues with Noga Engineering, Hamlet, Lev Mavletin, ML Mavletim, Emi Systems, Shvav Mag, D&S and others.

SolidCAM continues to dynamically advance, while listening to the demands of its customers and the manufacturing market and supporting the highest technological needs in the various types of CNCs.